Achieving guarantee of grain quality safety

Measurement and control of grain condition

Mechanical ventilation

Grain cooling

Airtight storage

Precise measurement and control

The grain silo is equipped with easily-operated electronic sensing element used to detect temperature and humidity, so that temperature and humidity in the silo can be controlled at any time, and the data can be saved and printed.

.jpg)

Mechanical ventilation

According to the indication of temperature measuring system, fan is timely started for heat exchange between cold air and materials in order to achieve the purpose of cooling and dehumidification.

.jpg)

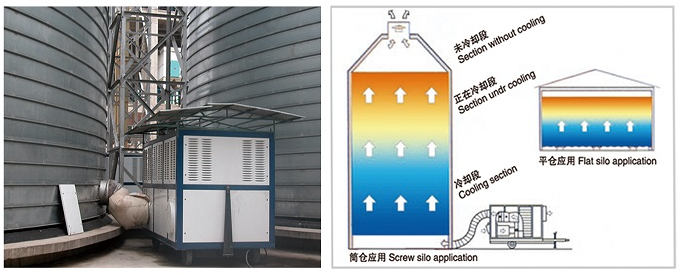

Grain cooling

Frozen storage can greatly slow “breathing” of grain to ensure long-term storage and freshness of grain and prevent breeding of insects. While cooling, grain moisture can be maintained or adjusted appropriately; it has three functions: cooling and ventilation while maintaining moisture; cooling and ventilation while reducing moisture; cooling and ventilation while conditioning. It is an important technical measure for green grain storage and preservation and can be used to maintain and improve quality of grain stored in the silo.

Airtight storage

Airtight storage is applied to grain to effectively kill the insects and to prevent mold from growing, thus ensuring safety storage of grain.